SKIVE AND HEM

Container forming, co-packing, and high-resolution

graphics printed with in-house inks

Skive and Hem SeamSeal™ Technology

Skive and Hem SeamSeal™ Technology

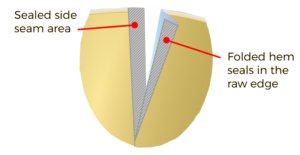

Our newest innovation, SeamSeal™ technology extends shelf life and offers advanced product protection. This technology utilizes a skive-and-hem application, which has traditionally been used for liquid packaging.

The skive and hem process requires specialized equipment to effectively embed the inner raw edge of the barrier-coated paperboard into the sealed side seam, preventing migration of moisture, grease, or oxygen through the exposed raw edge. These containers extend shelf life and offer a paper-based packaging option for many food products which historically have been confined to plastic, foil, or glass packaging due to high barrier requirements.

Barrier Options:

• Polyethylene: Moderate moisture and grease hold-out

• Polypropylene: Advanced moisture and grease hold-out and microwavability

• Foil Board: Superior oxygen and moisture barrier

Advantages:

• Consumer convenience

• Cost efficient

• Ease of handling for retailers

• High-impact graphics

• Superior shelf presentation

• Sustainable packaging

• Variety of barrier options to keep food fresh

Applications:

• Cereals

• Chocolates

• Confections

• Frozen foods

• Fruits

• Nuts

• Shelf-stable meals

• Snack products

Pioneering Innovative Packaging Solutions

© 2025 Interpress Technologies, Inc.

1120 Del Paso Road

Sacramento, CA 95834

(916) 929-9771

595 Grupe Street

Roberts, WI 54023

(715) 808-0282